Our Facility

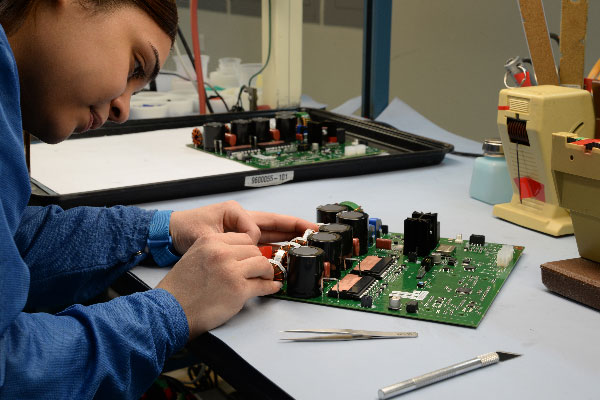

ESD

Protecting our customers’ circuit board assemblies from electrostatic discharge was a top priority in the design and outfitting of our facility. Conductive flooring and multiple paths to earth ground were incorporated throughout the building to guarantee the effectiveness of our extensive ESD system. The system is based on ANSI/ESD S20.20 – 1999 and includes ESD awareness training and the use of ESD wrist straps, heel straps and lab coats. In addition, all work surfaces, handling trays and carts are constructed of static dissipative material and are tested regularly to guarantee the proper protection of your parts.

Environment

Temperature and humidity are monitored and controlled through the use of multiple air make-up units. Each spray booth uses its own dedicated unit to guarantee the optimal conditions for the application of each specific coating type.

Security

As an ITAR registered company, numerous security measures, including the use of surveillance cameras and the availability of locked storage areas, have been taken to ensure the safety of sensitive customer product.

Equipment

Hand Spraying:

- 6 separate production spray booths dedicated by coating type

- 2 touch-up booths

- 1 booth dedicated to R&D project work

- A variety of HVLP & standard siphon feed spray guns

Automated Coating:

- (2) PVA-650 Selective Coating Automated Dispensing Systems

- Asymtek C740 computer controlled selective coating machine with board inverter

Curing

- Conventional ovens: 11 forced convection ovens

- Infrared: Nordson Select Cure Infrared oven

- UV: PVA UV2000 uv cure oven

- UV: Dymax UVC-12 uv cure oven

Ready to get started? Request a Quote.