The Coatings Experts

Your One Stop Coatings Provider

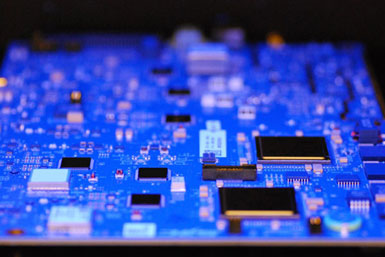

We’re known as the industry leader in providing innovative and highly effective Conformal, Dielectric, Conductive, and Biomedical Surface coatings, but there’s a lot more going on behind the scenes that makes us the One Stop Provider for all of your coating needs.

When you trust your product or assemblies to Jaro, they get VIP service from start to finish. Here’s how…

Products and Processes

With over 30 years of experience, we are specialists in the precision application of Conformal, Dielectric, Conductive, and Biomedical Surface coatings on a wide variety of products and assemblies. When your product or application needs a coating solution, we’ve probably seen it. We utilize state-of-the-art cleaning, surface preparation, and material application to provide consistent results –every time!

Preparation

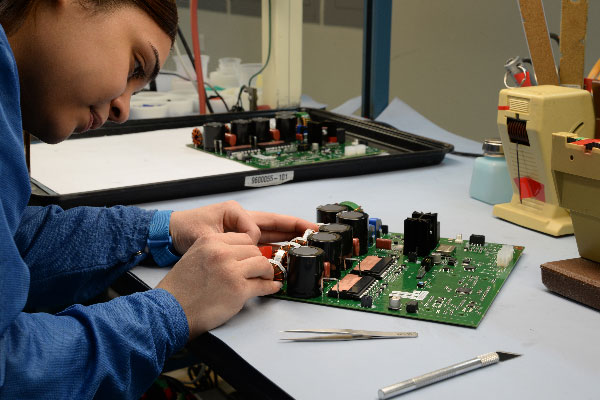

Good results require good preparation to make sure that coatings are applied only where needed. Our highly experienced masking and preparation technicians assure that the non-coated components such as connectors, sockets, etc, on your assemblies are fully protected during the application process. Skilled application means easy and effective removal without damage when completed.

3-Way Protection

ESD: Protecting our customers’ circuit board assemblies from electrostatic discharge was a top priority in the design and outfitting of our state of the art facility. Conductive flooring and multiple paths to earth ground were incorporated throughout the building to guarantee the effectiveness of our extensive ESD protection system. The system is based on ANSI/ESD S20.20 – 1999 and includes ESD awareness training and the use of approved ESD wrist straps, heel straps and lab coats. In addition, all work surfaces, handling trays and carts are constructed of static dissipative material and are tested regularly for compliance.

Security: As an ITAR, AS9100D, and DFARS registered company, numerous security measures, including the use of surveillance cameras and the availability of locked storage areas, have been taken to ensure the safety and security of sensitive customer products and related documentation.

Environment: Temperature and humidity are monitored and controlled through the use of multiple air make-up units. Each spray booth uses its own dedicated unit to guarantee the optimal conditions for the application of each specific coating type and elimination of any product cross-contamination.

People

Nothing happens without people, and we have the best! We have been able to attract skilled, dedicated professionals that make sure that our customers get the best service, support, and finest coating products available today. It’s what we do – every day!